Updating Your SMAN/Testo Gauges

Some of you might have an older SMAN/Testo digital gauge. With the new refrigerants coming, you might need to update

Technical Services Manager

North Georgia District

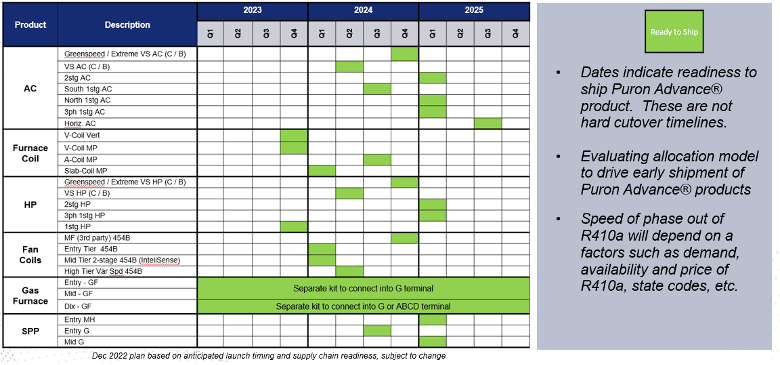

It’s coming soon. Below are the speculated dates of the release of Puron Advance, or R 454b in Carrier/Bryant equipment. These dates indicate readiness to ship the Puron Advance product. These are not hard cutover timelines. The speed of R 410a phase out will depend on factors such as demand, availability, and price of R 410a, state codes, etc. Actual first use of R 454b will be determined by the above factors.

In this article, we will cover a few key topics that will explain a few details pertaining to the use of R 454b. This information in this article only covers residential split ducted equipment. It does not apply to ductless, VRF, or commercial. We will cover ductless, VRF, and commercial, and more details on residential equipment in future newsletters. This briefing will give a few important details to prepare you for the change in refrigerants in Carrier/Bryant equipment. As always, safety is of main concern with the A2L refrigerants. A few things are still up in the air, under research and could change as new information becomes available. We will add new research changes in future articles and at our Fall and Spring Updates. But remember, as with anything new, keep yourself educated by reading and asking questions to learn as much as you can about new products. Much of the information in this newsletter is in Partners and My Learning Center.

Now we’ll talk about some primary concerns with equipment containing slightly flammable refrigerants. One of the primary concerns is the ignition of refrigerant leaking during equipment operation. Follow best practices when servicing the equipment to keep yourself safe and lower the possibilities of igniting any leaking refrigerant. One thing is for sure, be prepared and have a fire extinguisher available at all times when installing or repairing equipment with slightly flammable refrigerants. As mentioned earlier, a few things are still up in the air and could change as information becomes available.

Most A2L refrigerants are difficult to ignite because they have a high MIE or minimum ignition energy. Many common household items like a cordless drill, toaster, hair dryer, or electric heater will not ignite A2Ls. They require higher concentration levels to achieve a flammable mixture.

So what type of tools will be needed to work with Puron Advance? Well it requires the use of hand tools and equipment with no spark and no ark. Make sure all the tools that you are purchasing and using are UL certified. Your current gauges, digital or analog and hoses used with R 454b can be the same as used today, however, a dedicated set should be used the same as when working on R33 and 410a to avoid cross contamination. Check with the manufacturer to make sure equipment is rated for use with R 454b. 454b cylinders will have a red top and the hose connection will be reverse threaded. As always, before beginning work, make sure equipment is properly grounded.

Now we’ll talk about some primary concerns with equipment containing slightly flammable refrigerants, or A2L refrigerants. One of the primary concerns is refrigerants ignition of a refrigerant leak during equipment operation. We will cover this concern next in the indoor unit operation.

There will be several component changes from the standard 410a systems. Indoor Equipment Indoor equipment will require an active mitigation board and refrigerant sensor. In other words, if refrigerant is present then equipment operation will be interrupted and the indoor fan will be energized to dissipate the refrigerant and lower its flammability level. The sensor will continually be scanning for R 454 b leaks. It will also have an updated wiring diagram. The indoor unit will have a sensor factory installed for vertical orientation, other location will be clearly identified for different applications. For furnaces only, you will mount the mitigation board to the side wall of the furnace in the blower compartment. 24 volts ac will power the mitigation board and Y/Y1 from the thermostat will connect to the mitigation board. The fan wire ( G ) from the mitigation board to furnace control board will control the fan if leaking refrigerant is detected. When powered up there will be a 10 second sensor warm up delay. After the warm up you can use the mitigation board self-test button to test the connection, this will have a 60 second mode. The mitigation board will have a green LED for normal operation, and a red LED for mitigation mode. When the mitigation board is triggered the safety chain interrupts Y/Y1 to the outdoor unit shutting it off. The blower will stay on for 5 minutes after the sensor readings are below mitigation level. After 15 minutes of mitigation the unit is allowed to heat or cool again. If the sensor over heats it will send the unit into mitigation mode. During this time the blower is always on in this mode.

The TXV will be designed for R 454b. New safety labels will be apparent throughout the indoor equipment.

On the outdoor unit, the new compressor will be designed for R454b. It will also have a new A2L design contactor. The new A2L contactor will have a top cover with a small hole to access push button. There will be minimal air gaps inside the contactor to act as a flame arrestor. There will be wire sleeves on some high voltage wiring. It also will be having new safety labels throughout the outdoor system.

We need to make sure the disconnect box is not mounted on the unit.

Let’s compare operating pressure vs. saturated temperatures of R 410a vs R 454b. If we have a saturated suction temperature of 40 degrees Fahrenheit. The suction pressure of R 410a equals 118.8 psig. With R 454b, the suction pressure will be 113.3 psig . If we have a saturated condensing temperature of 110 degree Fahrenheit, the pressure of R 410a will be 366.4 psig. The R 454b pressure will be 349 psig. So these pressures are definitely not the same, but a small difference is apparent.

There is much more information forthcoming relating to R-454b. We are only scratching the surface. This newsletter may bring more questions than answers. That is OK. The more questions we get, the more we can all learn as we get the answers thru solid research and development. Remember as with anything new, research is constantly being conducted to improve the product. Change is inevitable as we find out new information. Stay tuned for much more in future newsletters.

Disclaimer: The technical statements, information and recommendations contained herein are believed to be accurate as of the date hereof, but Mingledorff’s does not make representations or warranties, express or implied, as to its accuracy, its completeness, or the results to be obtained. The information is being provided for informational purposes only and is intended for use by persons having adequate skill and expertise regarding the proper selection, use and application of the products and recommendations and at their own risk and discretion.

Some of you might have an older SMAN/Testo digital gauge. With the new refrigerants coming, you might need to update

Ladder diagrams, also known as ladder logic, are a type of electrical notation that illustrates how relays and electromechanical switches

All ducted VRF systems come from the factory set for 0” of static pressure. As we know from experience, this

Keep up with the latest HVAC news from Mingledorff’s Inc.