Vacuum Pump Performance

Most technicians are aware of the importance of changing the oil in your vacuum pump regularly. However, if you aren’t,

Technical Services Manager

North Georgia District

First, let us start by saying there are a variety of capacitors in various shapes, sizes and colors. For the purpose of this article, we will just be talking about run capacitors, dual capacitors and I’ll offer a brief explanation of start capacitors. We will not go into how capacitors work because this is strictly for testing purposes only when you are out in the field.

Please, before ever attempting to do these procedures, be safety conscious about what you are doing. Always discharge the capacitors with a discharging tool, which can be found online. Never touch a capacitor until you have done so.

You might say: the system is running, so the capacitor must be good! That is not 100% true. Now let’s see why.

A capacitor has a voltage rating on it such as 370 vac or 440 vac. So, anytime you exchange it with a new one, make sure you get the voltage that matches or is greater than the one you are replacing. Also, remember to get the manufacturer rated capacitor for the motor. Do not replace with a different size microfarad.

Capacitors are used on motors to make them more efficient by increasing the RMS (Root Means Square) of the sine wave. Capacitors increase efficiency by taking the load off the windings and they have a range for tolerance. For example, a 5 microfarad capacitor with a +/- 5% tolerance means that 5-microfarad x .05 (which is 5%) = .25 tolerance. You can add 5 or subtract 5 and that will be your range. In this example, it would be a range of 4.75 to 5.25 microfarads. If you put your meter on microfarads and measure the capacitor from one side to the other and it reads 4.25 or 5.75, it will be out of range. This makes the motor less efficient and should be replaced. You should also check the new one as well because you can get one out of tolerance right out of the box.

Start capacitors are usually made of a composite material. They are usually black or brown but they can be other colors as well. They are rated in ranges such as 150 to 275 microfarads. That is how you can tell that they are start capacitors because they are only used for a moment to boost the starting of the compressor.

A run capacitor is in the circuit the entire time the motor is running. Typically, they are in a metallic shell and they come in various shapes. For example, it can be a round canister looking object or it can be oval looking cannister. Run capacitors can have either two or three terminals to put wires. Each terminal can take 1-4 wires. The capacitors with just two terminals are called run capacitors and the ones with 3 terminals are called dual capacitors. The only difference between single vs dual capacitors is that dual capacitors internally share one point – which they call “common”. The other two terminals are called herm and fan. Herm for the compressor and fan is for the fan.

As a reminder, you have to read the tolerances of the capacitors each time you use one and remember that some manufacturers make the plus and minus tolerances different. For example, some might have a tolerance of +10%/-5%.

When you test a dual capacitor, always remember to discharge it before continuing. You have to measure from the common to herm and the common to fan and determine the tolerance for both. This would be like testing two single capacitors but this one shares one terminal – the COMMON!

You may see μF on your meter or MFD. They both stand for “microfarad”. Learn your meter with no power before you learn with power. Again, safety first!

Remember this is live and to use extreme caution during this process!

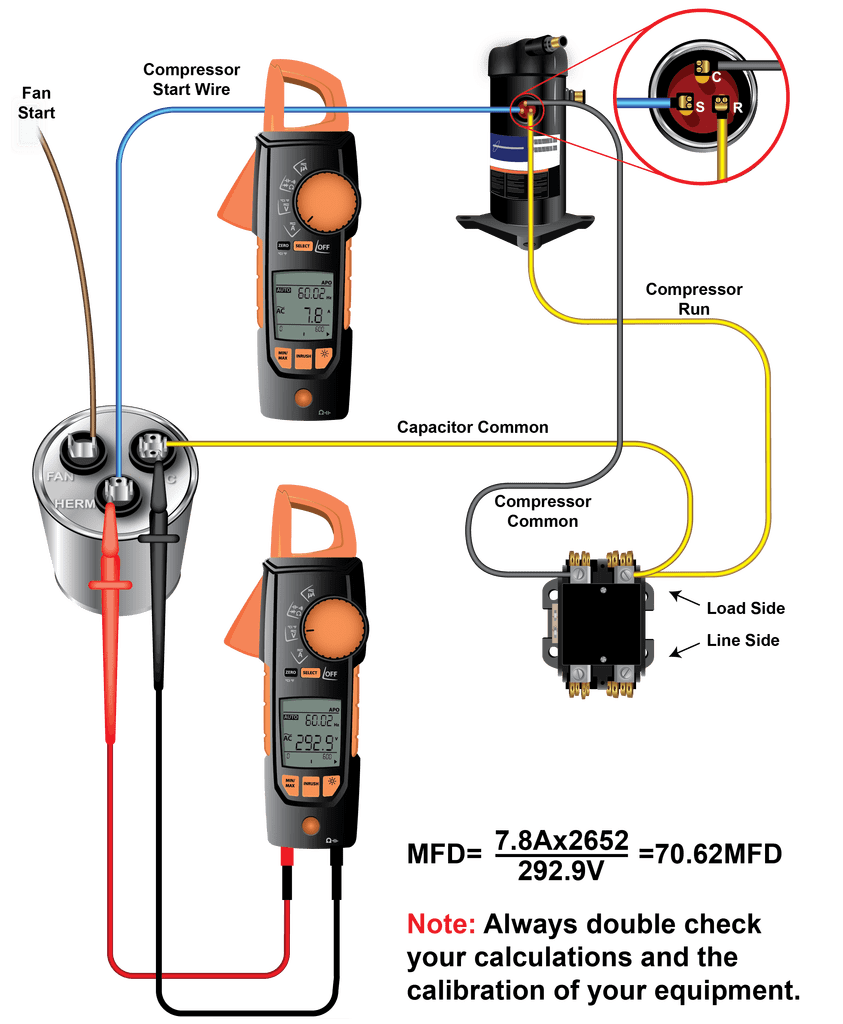

In the picture, the top meter is measuring the amperage or amps of the herm wire which is the compressor side of the capacitor. The bottom multimeter is reading the voltage from the herm wire to the common. The formula to calculate microfarads is shown with values from the example.

MFD = (Amperage x 2652) / voltage

Simply measure the voltage from the herm to the common on the capacitor and write it down. Then measure the amperage of the herm wire coming from the capacitor to the compressor and write it down. Plug the numbers from your readings into the formula to find the microfarad reading.

Most technicians are aware of the importance of changing the oil in your vacuum pump regularly. However, if you aren’t,

Installation of a heat recovery VRF system allows multi-zone heating and cooling. A heat recovery system allows you to heat

There are many different options and advantages to using a ductless mini-split system. From new construction installation to a retrofit